UPB Holding’s metalworking company RK Metāls has completed an upgrade of its factory, commissioning new energy-efficient and eco-friendly equipment: the TRUMPF TruLaser 3030 TruFlow 500 CO2 laser-cutting machine, the Hexagon ROMER Absolute Arm portable measuring arm, as well as the DURMA ADS 25100 hydraulic press brake. The project of the factory upgrade was conducted in cooperation with the Norwegian Financial Instrument 2009—2014 ‘Green Industry Innovation’ programme and the Investment and Development Agency of Latvia (LIAA). The total amount of investments in the project exceeded 620,000 euros.

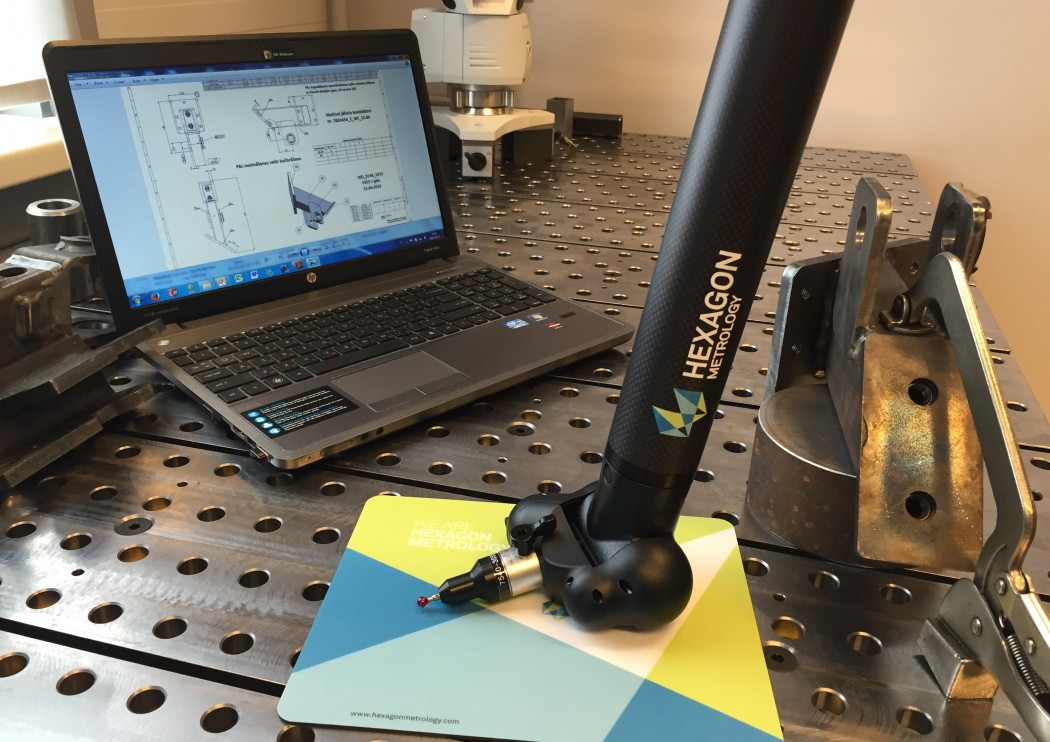

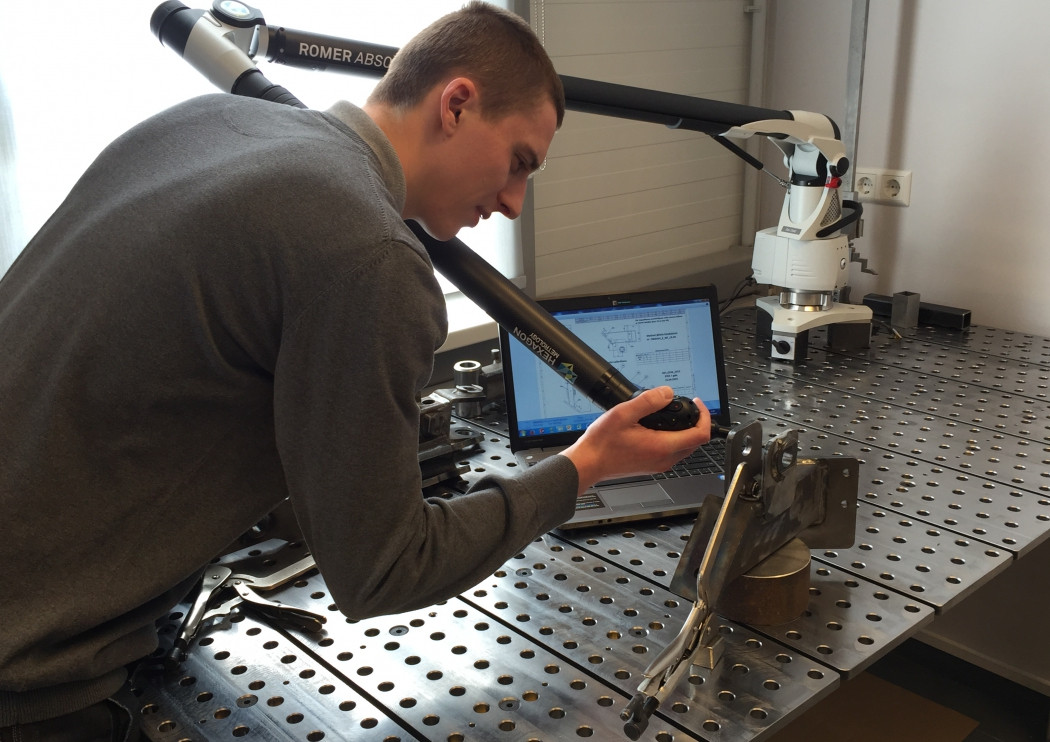

ROMER Absolute Arm portable measuring arm — a new type of quality control

ROMER Absolute Arm portable measuring arm allows checking for deviations in the geometric dimensions of large and small components, the measurement of which cannot be done using traditional touch probing methods. ROMER portable measuring arm can help to maintain production quality control by comparing the actual geometric dimensions to those included in the design, as well as to make 3D models based on the measurements obtained from physical components. Along with installing the portable measuring arm, RK Metāls was granted a document allowing the company to provide certified measurement services, and issue product geometric deviation and comparison certificates, which confirm and guarantee the quality of such measurements.

ROMER Absolute Arm

ROMER Absolute Arm is a mobile 6-axis coordinate-measuring machine made out of thermally inert carbon fibre. The machine copies the movements and the reach of the human arm, including the shoulder, elbow and wrist joints — and improves on them. Each of the axes has a sensor that detects the actual angle of rotation used to calculate the coordinates of the centre of the probe. Portable measuring arm is equipped with a tactile feedback motor that warns the operator of situations when a measurement could have been read incorrectly by sending a vibration signal. At the end of the arm, its sensor —a corundum ball— is inserted.

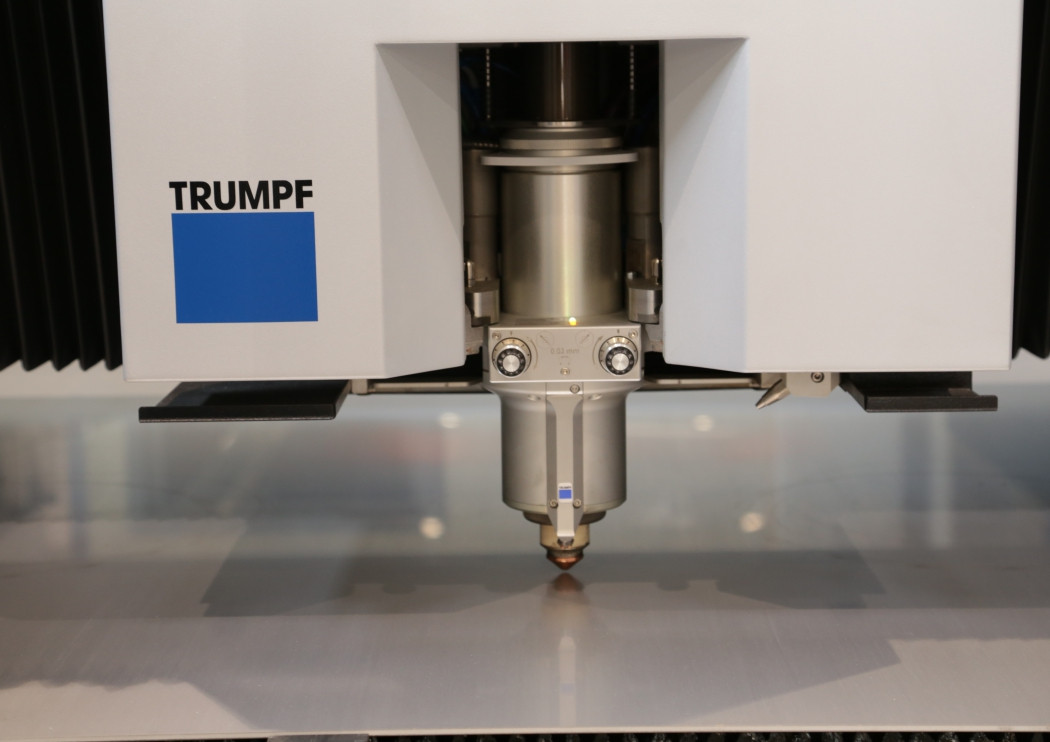

New TRUMPF TruLaser 3030 TruFlow 5000 laser cutting machine — for faster and more efficient processing of metal sheets

The new CNC laser cutting machine optimises the production process, with an improved user programming environment: the machine itself offers the most cost-efficient and effective processing modes, a higher cutting precision with up to +/--0.05 mm, and, therefore, a higher quality. The new TRUMPF laser-cutting machine has more resonator power and allows processing thicker sheets (up to 25 mm) at higher processing speeds.

DURMA ADS 25100 hydraulic press brake

The new DURMA CNC hydraulic press brake optimises the production process; it provides an all-round access to sheets and shapes of various types: thin and thick, narrow and wide.

Norwegian Financial Instrument ‘Green Industry Innovation’ programme

The implementation of the ‘Green Industry Innovation’ programme is conducted by its operators, the Ministry of Economics of the Republic of Latvia and the Investment and Development Agency of Latvia, as well as by the partner representing the donor country — a state company of the Kingdom of Norway, Innovation Norway.

‘Green Industry Innovation’ is one of the 8 programmes implemented in Latvia as part of the support offered by the Norway Grants Norwegian financial instrument for the years 2009—2014. Its goal is to create a Green Technology Incubator that will offer its services for the development, growth and commercialisation of innovative, technology-intensive and scientific ‘green’ ideas.