Enginnering

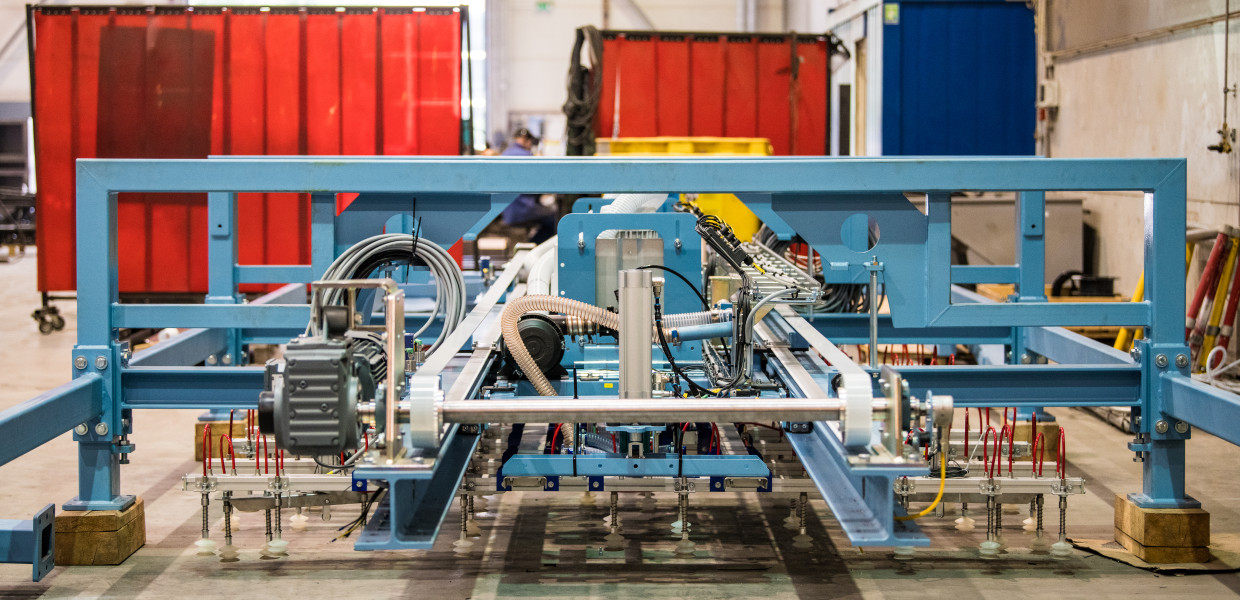

Our experienced mechanical and mechatronics engineers work closely with the production team to ensure a seamless transition from design to manufacturing.

We specialize in product concept development, CAD modeling, and prototyping, refining designs and eliminating manufacturing challenges. With advanced CAD, CAE, and CAM software we improve efficiency, precision, and quality, delivering reliable and cost-effective solutions with the highest production standards.